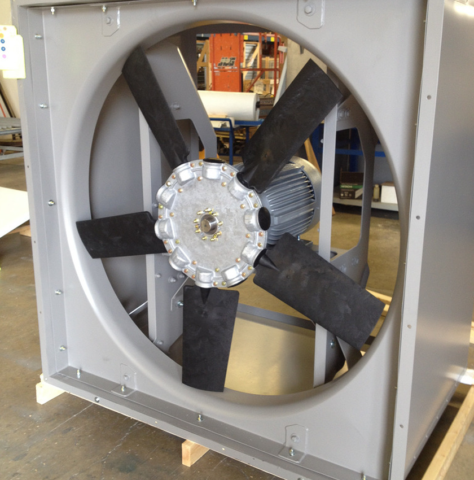

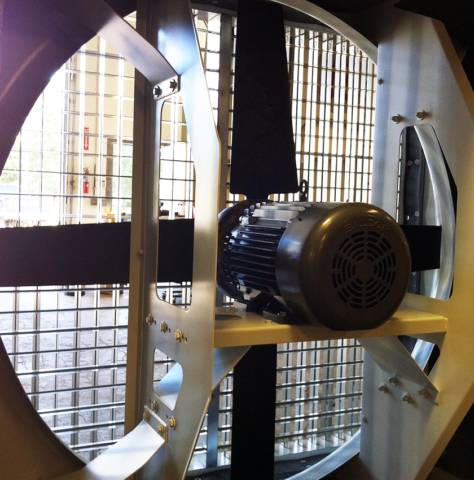

Each and every fan produced in the industry has a specific signature to their performance. At our Stafford, Texas facility, we design and produce our own line of industrial axial panel fans to accompany associated air moving equipment. We can provide you with your signature! Each fan is different by design, and each system develops a signature. With a signature you can develop and trend. Through that trending, we can determine that a specific order or grouping of fans are running similar to each other. Furthermore, IVS has field capabilities to compare the quality test signature to the installed fan signature. These onsite services are available upon request. We are more than happy to validate your installations.

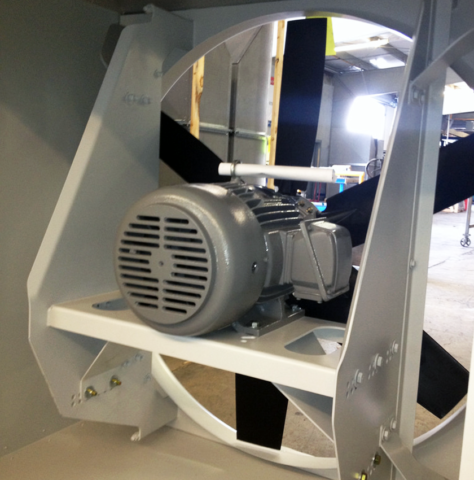

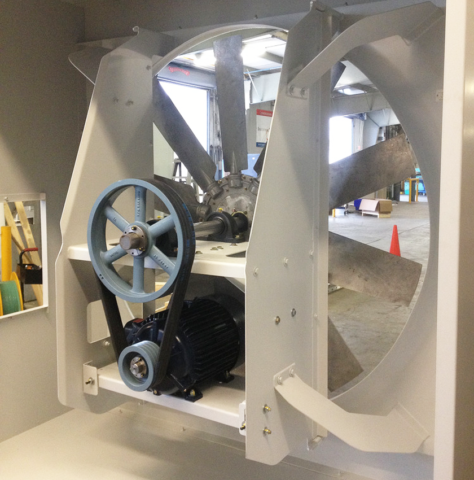

Rigid frame structures have been developed and continuously revised through sophisticated vibration analysis software and programs. We now have the experience to assure we meet the balance and vibration requirements of the AMCA standard which we apply ourselves to. Each fan produced is run tested to verify and prove that our fans pass this rigorous standard. A serial number and data sheet are produced with every fan as well as a vibration signature and timed recording of the test run. We verify amp draw to the motor name plate as well as compare the amp draw to the designed fan curve. You would be surprised at what is found during this testing. Those other manufactures who do not test each unit can only assume that their propellers are dynamically in balance, perfectly assembled and seated square on the shaft, and that the motors themselves are not creating a damaging vibration. We have found singular blades to be out of pitch by one degree that have put the fan out of its passing mode creating an unstable vibration. Unless requested, most propellers are statically balanced, meaning not in rotation. Static balancing would not pick up a blade out of pitch. We see it quite often. This testing is to our customer’s advantage as well as ours. We stand behind our products and services! We guarantee it!